Complex solutions for food producers

Equipment for production, preparation and storage of foods

Pressure vessels

Stainless steel pressure vessels are used in various areas of the food industry. The construction of pressure vessels is an essential part of our production. Vessels are manufactured according to customer requirements and specifications.

Stainless steel pressure vessels are enclosed horizontal or vertical cylindrical vessels with conical or arched bottoms and lids, usually equipped with legs and height adjustable screws. As a standard, we manufacture vessels according to customer specifications up to 4.2 m in diameter.

Non-pressure vessels

Stainless steel non-pressure vertical vessels are used in all areas of the food industry as storage, reservoirs or master containers.

Stainless steel non-pressure vessels are closed cylindrical vessels with conical or arched bottoms and lids, equipped with legs and height adjustable screws. These vessels are not rated for inner pressure. As a standard, we manufacture vessels according to customer specifications up to 4.2 m in diameter.

Pressure vessels

Stainless steel pressure vessels are used in various areas of the food industry. The construction of pressure vessels is an essential part of our production. Vessels are manufactured according to customer requirements and specifications.

Stainless steel pressure vessels are enclosed horizontal or vertical cylindrical vessels with conical or arched bottoms and lids, usually equipped with legs and height adjustable screws. As a standard, we manufacture vessels according to customer specifications up to 4.2 m in diameter.

Non-pressure vessels

Stainless steel non-pressure vertical vessels are used in all areas of the food industry as storage, reservoirs or master containers.

Stainless steel non-pressure vessels are closed cylindrical vessels with conical or arched bottoms and lids, equipped with legs and height adjustable screws. These vessels are not rated for inner pressure. As a standard, we manufacture vessels according to customer specifications up to 4.2 m in diameter.

Vacuum vessels

Vacuum vessels are used in the food industry to thicken content by evaporation under reduced pressure. The reduced pressure is maintained by means of condensation of juice vapours and by extraction of non-condensible gases by a vacuum pump.

These vessels contain an inner vessel, a duplicate shell, a stirrer and the relevant equipment. The inner vessel is cylindrical with a hemispherical bottom and lid. Vessels are supplied with the fittings necessary for the operation of the double heating jacket or sheathing (safety valve, pressure gauge with condensing loop, condensate drain), fittings of the inner vessel and the water circulation pump / water ring pump.

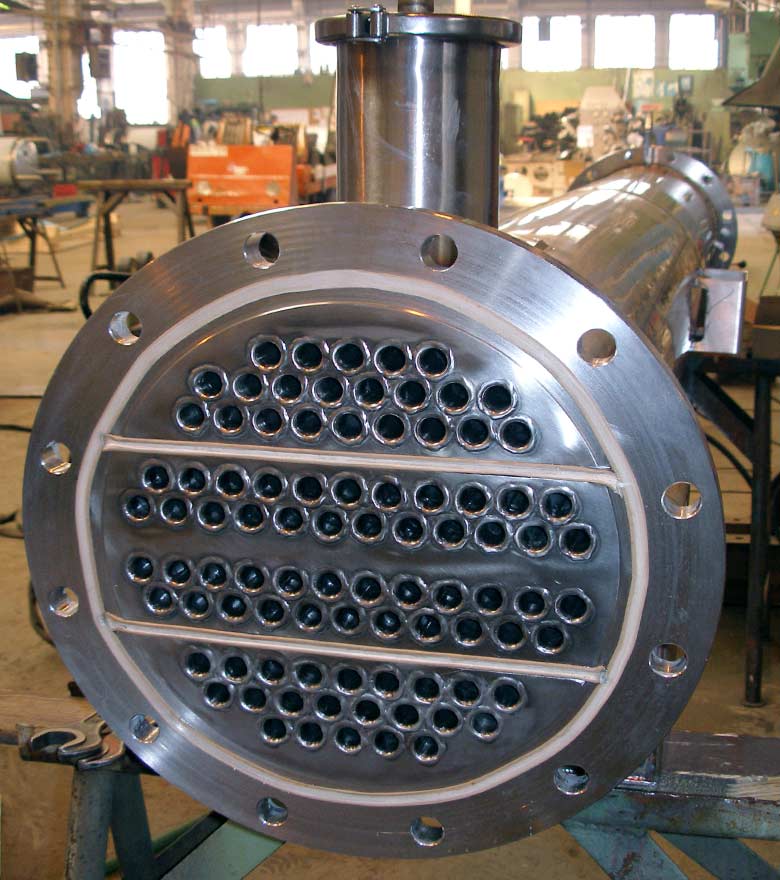

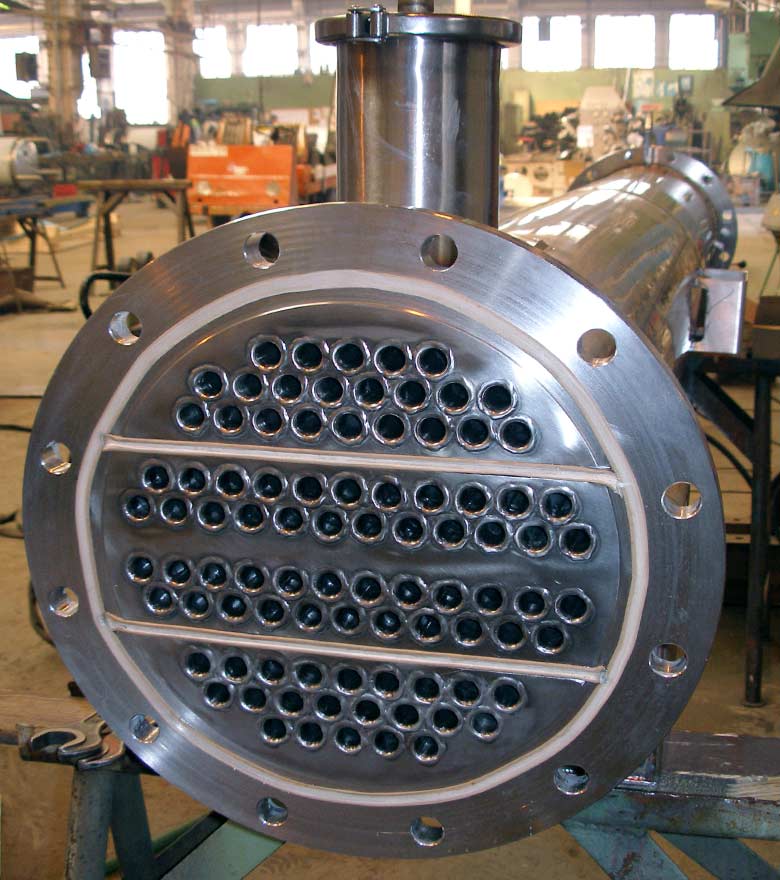

Tube heat exchangers

Heat exchangers are pressure containers positioned either horizontally or vertically. They are manufactured according to customer requirements in many sizes and offer various power outputs.

• fixed tube heat exchangers are used for heat exchange between liquid-liquid or liquid-vapour where there are lower temperature differences

• floating head heat exchangers are used for heat exchange between liquid-liquid or liquid-vapour media at lower temperatures

• hair U-tube exchangers (heating register) are used for heat exchange between liquid-liquid or liquid-vapour where there are lower temperature differences

Vacuum vessels

Vacuum vessels are used in the food industry to thicken content by evaporation under reduced pressure. The reduced pressure is maintained by means of condensation of juice vapours and by extraction of non-condensible gases by a vacuum pump.

These vessels contain an inner vessel, a duplicate shell, a stirrer and the relevant equipment. The inner vessel is cylindrical with a hemispherical bottom and lid. Vessels are supplied with the fittings necessary for the operation of the double heating jacket or sheathing (safety valve, pressure gauge with condensing loop, condensate drain), fittings of the inner vessel and the water circulation pump / water ring pump.

Tube heat exchangers

Heat exchangers are pressure containers positioned either horizontally or vertically. They are manufactured according to customer requirements in many sizes and offer various power outputs.

• fixed tube heat exchangers are used for heat exchange between liquid-liquid or liquid-vapour where there are lower temperature differences

• floating head heat exchangers are used for heat exchange between liquid-liquid or liquid-vapour media at lower temperatures

• hair U-tube exchangers (heating register) are used for heat exchange between liquid-liquid or liquid-vapour where there are lower temperature differences

Duplicator vessels

Duplicators are used in the food industry for heat treatment of raw foods. This creates different demands on the size, equipment, construction and material design.

We manufacture duplicator boilers according to the special technological needs of end users. Fixed duplicators consist of an inner vessel, a duplicate heating jacket, an outer insulating jacket and the relevant equipment.

Fruit and small grower distilleries

Fruit and small grower distilleries are designed to process fruit and wine mash and to create fine distillates.

Thanks to the use of modern technologies, a unique product is created that preserves all the benefits of the processed fruit and other raw materials.

All parts of the distillation set which come into contact with the processed mash or distillate are made of copper or stainless steel.

Duplicator vessels

Duplicators are used in the food industry for heat treatment of raw foods. This creates different demands on the size, equipment, construction and material design.

We manufacture duplicator boilers according to the special technological needs of end users. Fixed duplicators consist of an inner vessel, a duplicate heating jacket, an outer insulating jacket and the relevant equipment.

Fruit and small grower distilleries

Fruit and small grower distilleries are designed to process fruit and wine mash and to create fine distillates.

Thanks to the use of modern technologies, a unique product is created that preserves all the benefits of the processed fruit and other raw materials.

All parts of the distillation set which come into contact with the processed mash or distillate are made of copper or stainless steel.

Bulk storage tanks and storage silos

PACOVSKÉ STROJÍRNY manufacture large-volume storage silos and stainless steel tanks for bulk substances and liquids. They are designed for storage of food products, non-food plastic granules or building materials or possibly for liquids such as water, oils, alcohol or molasses.

In addition to production, our professional team also creates project documentation, handles installation, assembly and transport of oversized goods.

CIP sanitation stations

CIP sanitation stations are used for washing and rinsing of individual technologies that are used in all food processing operations. These devices are designed for preparation, storage, distribution and reuse of sanitary products and optimise their effect and consumption.

The basic composition of a CIP station includes a storage container for sanitary solution equipped with a lid, an electric or steam heater, a circulation pump, pipes and fittings and a simple or programmable control system.

Filtration devices

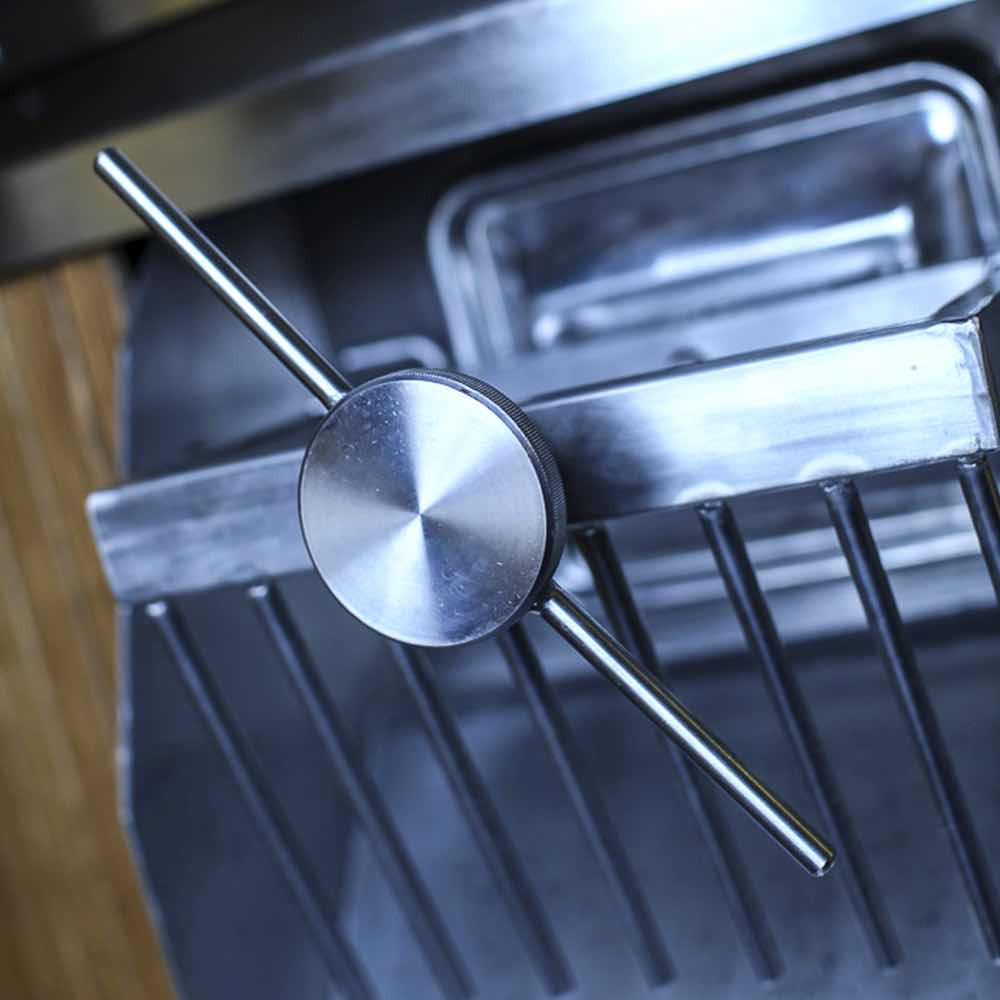

Cylindrical pressure vessel with hollow central shaft and disc filter elements. The blast of the filter cake is performed by means of centrifugal force – by rotating the central shaft with the filter discs.

All-stainless steel container, stainless steel or textile filter screens, central shaft drive.

Filtration of suspensions in the chemical and food industries.

Bulk storage tanks and storage silos

PACOVSKÉ STROJÍRNY manufacture large-volume storage silos and stainless steel tanks for bulk substances and liquids. They are designed for storage of food products, non-food plastic granules or building materials or possibly for liquids such as water, oils, alcohol or molasses.

In addition to production, our professional team also creates project documentation, handles installation, assembly and transport of oversized goods.

CIP sanitation stations

CIP sanitation stations are used for washing and rinsing of individual technologies that are used in all food processing operations. These devices are designed for preparation, storage, distribution and reuse of sanitary products and optimise their effect and consumption.

The basic composition of a CIP station includes a storage container for sanitary solution equipped with a lid, an electric or steam heater, a circulation pump, pipes and fittings and a simple or programmable control system.

Filtration devices

Cylindrical pressure vessel with hollow central shaft and disc filter elements. The blast of the filter cake is performed by means of centrifugal force – by rotating the central shaft with the filter discs.

All-stainless steel container, stainless steel or textile filter screens, central shaft drive.

Filtration of suspensions in the chemical and food industries.

Products for food industry

- Pressure vessels

- Non-pressure vessels

- Tube heat exchangers

- Vacuum vessels

- Duplicator vessels

- Fermentation dryers

- Fruit and small grower

distilleries

- Bulk storage tanks and storage silos

- CIP sanitation stations

- Filtration devices

- Autoclaves